Part C: The 2017 outage

PREVIOUS | NEXT | Return to CONTENTS

8. National and fuel sector systems for responding

to crises

8.1 Being well prepared and responding effectively are important components of a resilient system. In this Part, we consider the operational responses to the 2017 outage, its impacts, and the risk management practices of all those involved in it, including the emergency management organisations.

- This chapter describes the emergency response systems and preparations that existed in 2017 when the outage occurred, because they provide the backdrop for understanding what happened.

- Chapter 9 explains what happened on the day of the outage (Thursday 14 September 2017) and how Refining NZ worked to find the leak, fix the pipeline, and restore supply.

- Chapter 10 sets out the communication and coordination activities during the outage.

- Chapter 11 examines the steps that were taken to manage the effects of the outage, including setting up alternative methods of supply and rationing jet fuel.

- In chapter 12, we set out the lessons that we have identified from how the 2017 outage was managed and our recommendations on these matters.

New Zealand’s system of civil defence and emergency management

8.2 If an incident is larger than individual organisations can manage, New Zealand has a developed public sector system for responding to incidents and emergencies: the civil defence and emergency management system (CDEM system). It is triggered by the Government declaring a national emergency or a local civil defence group declaring a local emergency.

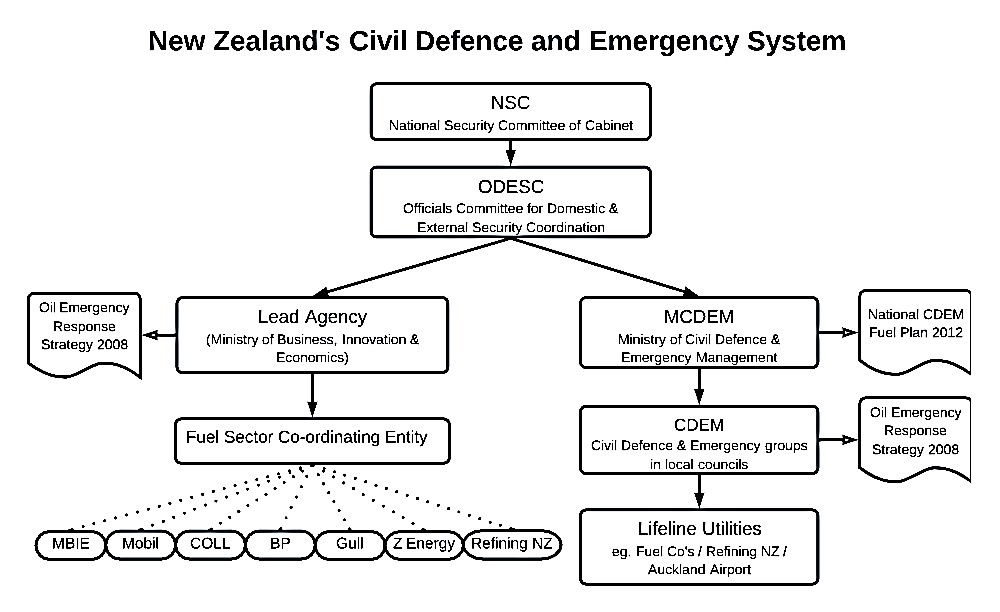

8.3 New Zealand’s CDEM system aligns with international practice by being built around “the four R’s”: reduction of risk, readiness for an event, response, and recovery. These four concepts permeate all layers of the system. Figure 5 provides an overview of the system.

National organisations and roles

8.4 The Ministry of Civil Defence and Emergency Management (MCDEM) is headed by the Director of Civil Defence and Emergency Management and has responsibility for the overall system and for managing national events. It administers the Civil Defence and Emergency Management Act 2002 (CDEM Act), which provides the legal framework for managing civil defence events and emergencies. The Director’s functions are both preparatory (identify nationally significant hazards and risks, maintain the national CDEM strategy and plan, and develop guidelines and codes to support work under the Act) and responsive (direct and control resources during a state of national emergency).

8.5 The MCDEM is supported by the Officials Committee for Domestic and External Security Coordination (ODESC) system, which is the system for oversight and governance of all national security issues, including significant crises or events that might need all-of-government planning and prioritisation. The aim is for agencies to work collectively to bring together information and coordinate analysis and advice for Cabinet.

Figure 5: New Zealand’s CDEM system

8.6 The CDEM system has three levels:

- National Security Committee of Cabinet (NSC): this is chaired by the Prime Minister and is where the Government makes decisions on national responses to major crises.

- Officials Committee for Domestic and External Security Coordination (ODESC): this is chaired by the Department of the Prime Minister and Cabinet (DPMC), which coordinates all-of-government responses to events and provides policy oversight and advice to the Prime Minister, Cabinet, and the NSC.

- Watch groups and working groups of senior officials, who monitor individual sectors and topics.

8.7 The lead agency for any emergency or crisis is the one with the primary mandate for managing the response. The lead agency is expected to monitor and assess, plan and coordinate, report to ODESC, provide advice, and coordinate public information. It does this using its own emergency management plan, functions, and powers. It should maintain its own capability and capacity to be able to perform this role when needed, although support from emergency management experts is available from MCDEM.

8.8 The National Crisis Management Centre (NCMC), run by MCDEM, is the central government facility for enabling national coordination and management of the response to emergencies. It is kept in a constant state of readiness and can be activated without a local or national emergency being declared.

Local and sectoral groups and roles

8.9 The CDEM Act requires every local authority to establish and maintain a CDEM Group: these are the core of the preparation and response machinery under the Act for a geographical area. Each CDEM Group must:

- identify hazards and risks and take steps to reduce them;

- ensure it has an organisational structure and competent and trained people ready to respond;

- respond and manage emergencies and recovery activities in its area;

- monitor and report on compliance with the Act in its area;

- develop, implement, and monitor a CDEM Group plan and review it regularly; and

- participate in the national strategy and plan work.

8.10 Clusters: A cluster is a group of agencies that work to coordinate CDEM-related activity, including planning, inter-agency communications, and access to shared resources. The cluster is a flexible concept that is meant to be flexible and self-organising, operating at national, regional, or local levels, and within or across sectors. One of the specified clusters is “lifeline utilities”.

8.11 Lifeline utilities are listed in the CDEM Act. They are organisations that provide essential and enabling infrastructure and services. Organisations involved in the production, supply, and distribution of petroleum providers are included in the list. Each lifeline utility has a duty to ensure that it can function as fully as possible during and after an emergency.

8.12 Sector Coordinating Entities (SCEs) are the main mechanism for coordination and communication between the NCMC and entities within a sector. They are meant to provide for pre-planned sector coordination through a single point of contact for each lifeline sector. They can also be part of a cluster. Their readiness activities are generally limited to establishing emergency communication protocols within the sector for all agencies with a response role. Some SCEs do more and facilitate sectoral emergency exercises and contingency planning. The arrangements differ across sectors.

Petroleum sector arrangements in 2017

Public sector planning

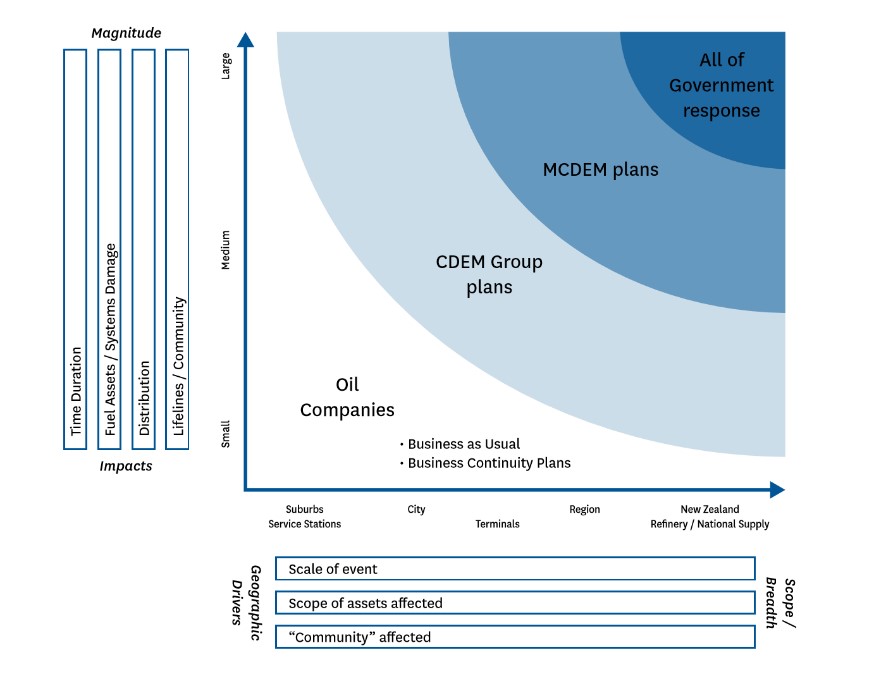

8.13 Within this overall system, the petroleum sector organisations make up a sector and are each lifeline utilities. MBIE is the lead government agency for the sector. Two documents describe the arrangements for a disruption to fuel supply: the Oil Emergency Response Strategy 2008 (the 2008 Response Strategy, published by MBIE) and the National CDEM Fuel Plan 2012 (the 2012 Fuel Plan, produced by MCDEM).

8.14 The 2008 Response Strategy is designed to address short-term fuel disruptions, coordinating as needed with the ODESC system and the business continuity plans of the individual companies. It makes clear that the fuel companies are initially responsible for responding to any disruption; it is only if an industry response is unlikely to be sufficient that the Government would become involved. It states:[1]

In general, oil companies will have the initial role responding to an oil supply disruption. However, if the severity of the situation warranted it, the government could assist industry and intervene using the legislative and non-legislative measures contained in the Strategy and/or civil defence powers.

8.15 Under the Strategy, MBIE’s key function is to convene and lead the National Emergency Sharing Organisation (NESO) required under the International Energy Agreement. MBIE is to collect information from the industry through NESO and use that information to provide advice to government, including advice on whether government involvement in a disruption is required.

8.16 The framework for assessing where responsibility sits is shown in Figure 6.

Figure 6: Response arrangements for the oil sector[2]

8.17 These layers of responsibility are repeated in the 2012 Fuel Plan, which also contains more operational detail. It sets out the “readiness planning framework” for the sector and national-level communication and coordination arrangements for response operations. It is designed for an emergency or event that is likely to have a major effect on national or regional fuel infrastructure or distribution. It focuses mainly on ground fuels.

8.18 The 2012 Fuel Plan sets out the details for an agreed coordination process, centred on a teleconference. This teleconference forms the national Fuel Sector Coordinating Entity(Fuel SCE, which is effectively the same as the NESO). It is activated and chaired by either MBIE or the NCMC (depending on the level of the crisis). The participants in the Fuel SCE are listed as COLL, Refining NZ, Mobil, Z Energy, Chevron (bought by Z Energy in 2016), BP, Gull, and the relevant government agency.

8.19 For the Inquiry’s purposes, the other relevant part of the 2012 Fuel Plan is the information-reporting system that it sets up. The various companies are required to provide:

- the status of their facilities and transport networks;

- confirmation of fuel stocks by type and location;

- estimates of future changes to stocks;

- estimates of emergency demand levels;

- their capability to supply critical customers; and

- their overall ability to manage demand.

8.20 In addition, there is the Auckland Region Fuel Contingency Plan 2016, prepared by Auckland Council. Like the 2012 Fuel Plan, it is primarily concerned with ground fuels and arrangements for prioritising allocations of fuel to lifeline utilities and critical customers in a full emergency. The 2017 outage did not reach this level of seriousness and no prioritisation was activated under the Auckland or National CDEM Fuel Plan.

The individual companies

8.21 The individual companies and organisations in the fuel sector sent us their individual emergency response and business continuity plans. These were all comprehensive and up to date. We were told that each organisation carries out its own regular practice exercises. This level of focus on being able to respond to crises is not surprising in a high-hazard industry like the petroleum sector.

Sector-wide preparation and practice

8.22 MBIE told the Inquiry that the coordinating body, the Fuel SCE, meets by teleconference as needed when there is an emergency or elevated risk of supply disruption. It also meets in person for planning purposes. We were told that it is a small group and the standing teleconference system works well as a way of bringing people together. MBIE advised that the Fuel SCE last met for a workshop in November 2018 to discuss risk reduction and planning for regional fuel disruption scenarios.

8.23 The only recent exercise relevant to the fuel sector was Exercise Tangaroa, in 2016. This was a national CDEM sector exercise based on a scenario of an earthquake and tsunami. The scenario had a fuel sector element by incorporating significant damage to the fuel supply infrastructure, including the Marsden Point refinery, fuel tank farms located at ports, and wharves. The exercise showed that in this situation, it would be difficult to obtain refined fuel stocks and bring them to New Zealand before the stocks already in the country were depleted. It also found that damage to pipelines would leave Auckland isolated for fuel supply, especially for jet fuel. The Fuel SCE met after this exercise to discuss its implications.

8.24 There have been no group exercises for the organisations in the sector as a whole to practise preparedness and responses together and test the sector-wide plans.

9. What happened in September 2017[3]

Thursday 14 September 2017: the day of the outage

9.1 On Thursday morning, the RAP was moving a batch of jet fuel towards Auckland. The pumping system “tripped” and automatically shut down at 9.54am when someone working on the system caused a false fire alarm. Trips of this kind are reasonably common, for a variety of reasons. The control room team began the standard restarting process at 10.15am.

9.2 By 11.56am, the flow in the pipeline had reached about 60% capacity. At that moment, there was a sudden drop in pressure, which caused the pipeline to shut down automatically again. The control room operators followed established protocols and carried out a set of checks and tests before trying to restart it using standard procedures, but these attempts failed.

9.3 The monitors showed that a RAP valve at Waipū Cove, about 20 kilometres from the refinery, had closed as part of the safeguarding system and was preventing a restart. Further checks showed that the pressure was low at Marsden Point, for no clear reason. The control room asked a technician to go and inspect the valve at Waipū Cove. At 1.23pm, the technician confirmed that the pipeline pressure between Marsden Point and Waipū Cove was zero.

9.4 At 1.40pm, the control room notified the Pipeline Controller that there was a problem. At 1.45pm, Refining NZ initiated formal steps to prepare for a possible leak. At the time, the Pipeline Controller and colleagues were on a helicopter surveillance flight of the RAP in the Auckland area. They took a helicopter from Ardmore Airport to go north and fly over the section of the RAP where the problem was. At 2.40pm, they saw a pool of fuel forming in a paddock at Ruakākā, confirming there was a leak. The Pipeline Controller relayed the location to the refinery.

Figure 7: Photograph of the leak site taken from the helicopter, 14 September 2014

9.5 Refining NZ initiated its emergency response procedure. The senior management team was told about the leak and the company notified emergency services, First Gas, NRC, and WorkSafe New Zealand. Shortly after 3pm, they sent crews and equipment to the site. The initial priorities were to ensure the safety of the site and of the people in the area (including staff and neighbours), and then to contain the spill, remove leaked fuel, and remediate the site.

9.6 The site and surrounding areas were cordoned off, nearby residents were relocated, and access to the site was controlled. Work began to improve the access road and other infrastructure at the site so that heavy machinery and equipment could be brought on site. At the same time, they began to put in place barriers and booms to direct and contain the flow of fuel, and to remove spilt fuel using gully suckers, skimmers, and absorbent material.

9.7 Within four hours of the pipeline shutting down, Refining NZ had identified the location of the leak, secured the site, and started work to remove the fuel that had escaped. By late on Friday 15 September 2017, they had largely contained the spill.

Fixing the damage to the pipeline

9.8 The next step was to begin to excavate, to expose the pipe and assess the damage. At that point, the refinery had no information on why the pipe had leaked. Excavation was difficult because the area has a high water table and the ground was sodden from winter rain. The standard procedures for excavating around pipelines require the work to be done slowly and carefully. The last 30 centimetres was dug out by hand.

9.9 It took until 6pm on Friday 15 September to expose the 2-metre-deep pipe and see the damage. That was when it became apparent that the damage was not a small, or “pinhole”, leak but that the pipe had suffered a major rupture. It had significant gouges and cracks in it, suggesting to those examining it that it had been struck by something some time earlier. That damage had weakened the pipe so that it had eventually cracked and ruptured.

Figure 8: Photograph showing the damage to the pipeline

9.10 If the pipe had had a pinhole leak, which is a more common problem in underground fuel pipelines, Refining NZ had been ready to fix it by applying a clamp. A repair of this kind could have been completed within one to two days. However, the damage to the pipe was much more substantial. By the end of Saturday 16 September, the repair team concluded that the best repair option would be to weld in a new section of pipe to replace the damaged section. Across the next seven days they:

- finalised a repair plan and schedule, with input from a range of experts;

- excavated and removed water from the repair site, as well as at points on each side where the pipe would be blocked off while the repairs were carried out;

- replaced the damaged section with new pipe and welded it into place;

- developed a plan for restarting the pipeline;

- waited 24 hours, as required by safety standards, for the welds to be tested; and

- received certification from Lloyd’s Register, the external certifier, approving operation of the RAP at a reduced pressure.

Restoring supply

9.11 Restarting the RAP after an incident of this kind needed to be done carefully. Refining NZ was particularly concerned about the risk of an air bubble in the pipe. If air was sent down the RAP to Wiri, the pressure differential could damage the tank receiving the fuel.

9.12 They put water through the pipeline first, to displace any air, but this was not definitive. After consultation with industry experts, they slowly pressurised the line and opened the Waipū Cove valve to pressurise and fill the pipe with diesel from the refinery end. They used markers to monitor the progress of the contaminated fuel already in the pipeline and the clean fuel as it moved down the line to Wiri. They also sent two cleaning pigs down the pipeline to remove any rubble or smaller air bubbles that might be present.

9.13 The pipeline started pumping again on the afternoon of Sunday 24 September. The first fuel that arrived at Wiri was the three batches that had been in the pipeline when the rupture occurred:

- The first batch was jet fuel, which arrived at Wiri on Sunday 24 September, almost exactly 10 days after the outage occurred. It had been re-certified by Monday morning and was available for use at the JUHI that night.

- The second batch was diesel, which was available for use at Wiri by the morning of Monday 25 September.

- The third was another jet fuel batch, which arrived at the JUHI on Tuesday 26 September.

9.14 At the same time, the first new batch of jet fuel was being injected into the pipeline at Marsden Point. It was split into two smaller batches at Wiri, so that some could be sent through to the airport more quickly. The first partial batch arrived there on Thursday 28 September and the second on Saturday 30 September. A batch of ground fuel was sent down the pipeline next, followed by another batch of jet fuel.

Fixing the environmental damage

9.15 The automated shutdown of the RAP limited the amount of fuel that escaped into the surrounding land and waterways at the leak site. Refining NZ estimates that 124 m3 of fuel leaked in total. The refinery took prompt steps to contain the leaked fuel, including building weirs, drains, and walls to direct and contain it, and collecting and removing the fuel as well as contaminated water and soil. As a result, a relatively small area of land was affected and fuel did not escape further down the culvert or into the nearby river.

9.16 Over 115 m3 of the leaked fuel was directly recovered. Most of the remaining 9 m3 was removed with contaminated soil and groundwater and taken to Marsden Point for treatment.

9.17 NRC monitored the work site and surrounding environment throughout the process, testing the soil, waterways, and groundwater for contamination. This monitoring confirmed that the environmental damage had been effectively contained.

9.18 Refining NZ continued to work closely with NRC, expert advisers, local hapu, and the landowners of the three affected properties for several months after the incident, to achieve the full remediation of the properties. NRC’s files record that their incident file was eventually closed at the end of May 2018, when the contamination had been removed and drains reinstated. We note that the files record NRC’s view that the work to contain the spill and remediate the land was done to the highest standard.

Our findings on the physical response effort

9.19 We agree with NRC’s view, and find that the way in which Refining NZ responded to the leak was swift, well coordinated, careful, thorough, and effective. The planning and preparation they had in place for incidents meant that the operation ran smoothly.

9.20 We also record that the refinery received good support and assistance from many others, so that they could draw on the best expertise available. We acknowledge the help provided by First Gas, who gave extensive help with the excavation and welding; BP and Mobil, who provided engineering advice; Worley Parsons; and Lloyd’s Register.

10. Communication and coordination during the outage

10.1 This chapter discusses how the communication efforts during the outage were managed. In any crisis, clear communication and effective coordination are an important part of the response effort. This was a challenge during the 10-day RAP outage.

The organisations involved

10.2 The outage affected all of the organisations involved in the supply of fuel by pipeline to Auckland:

- Refining NZ owns the RAP and was responsible for fixing the problem, and had to communicate with its fuel company customers.

- The three fuel companies had to manage their own customers’ expectations and find alternative methods for supplying fuel to them.

- The infrastructure operators in the rest of the supply chain (WOSL, JUHI, and COLL) had to support their fuel company owners in finding solutions.

- The customers of the fuel companies – in particular, Air New Zealand and the other airlines that usually refuel at Auckland Airport – had to change their normal operations over this period.

- Other stakeholders, such as Auckland Airport and other airports around New Zealand and in nearby countries, became involved in the efforts to provide fuel for aircraft unable to refuel at Auckland.

10.3 Three of these companies are publicly listed (Refining NZ, Z Energy, and Auckland Airport), which means they also had obligations to disclose any significant information to the stock exchange.

10.4 There was obviously significant public interest as well, as the travelling public wanted to understand the effect on their ability to continue to drive or fly. Businesses and organisations that depend on fuel of one kind or another for their operations were also monitoring the situation closely.

10.5 As a result, central and local government agencies took a close interest. If the situation had become severe, they might have needed to activate emergency response measures. For Ministers, this was a time of heightened sensitivity, given that the general election was being held on 23 September 2017. The list of agencies involved was long. The central government organisations included:

- MBIE, which has policy oversight of the petroleum sector;

- MCDEM, which coordinates and supports the overall system in New Zealand for all crisis and emergency responses;

- DPMC, which has a coordinating role in any significant issue that might require an urgent government response;

- Ministry of Transport (MOT), which advises government on all forms of transport;

- New Zealand Transport Agency (NZTA), which administers the rules governing transport activities;

- WorkSafe New Zealand, which is responsible for the health and safety rules governing dangerous workplaces; and

- New Zealand Defence Force (NZDF), which had the potential to deploy personnel and/or practical resources if required.

10.6 The local authority most directly concerned was Auckland Council, given its responsibilities for local emergency management. Its council-controlled organisations, Auckland Transport and Panuku Development Auckland, were also involved. Other local authorities with an interest included NRC and the Waikato Regional Authority.

How and when information was shared

10.7 Table 6 sets out the steps that were taken to communicate information and establish coordination mechanisms, across the period of the outage.

Initial communication about the outage

10.8 As soon as it identified the site and confirmed the leak on Thursday 14 September, Refining NZ informed its senior management team, the Minister of Energy and Resources, MBIE, WOSL, and the supply managers of its fuel company customers that the RAP had experienced a leak. Others, including First Gas, were also informed through the course of the day.

10.9 An email to the fuel company supply managers at 3.30pm said, “at this stage we do not anticipate an impact on Auckland product supply”, but that supply managers would be kept updated as new information came to hand. A second email just after 4pm advised that “very first indications are that we may experience a minimum of 48 hour outage of the RAP. This is preliminary and may prove to be conservative. We will keep you informed.”

10.10 The estimate of 48 hours was confirmed as still being current at the end of the day. Refining NZ confirmed it for supply managers, released a Facebook post, and prepared a media statement, which it shared with the fuel companies and MBIE but did not release publicly. The draft statement said that “an early estimate is that the pipeline recovery and repair will take two days to complete, after which a controlled restart of the pipeline will take place.” This is consistent with what MBIE, WOSL, Air New Zealand, and others told us that they understood on that first day.

10.11 As the site was excavated during the following day, Refining NZ updated its message to the supply managers on the possible repair time. It held a teleconference with them at 11am, noting that the full scope of the repair would not be known until the pipe could be visually inspected. The supply managers were informed that the repair could take between two days and a week (from the following morning), depending on what type of repair was needed. The fuel companies passed that information on to MBIE.

10.12 On Friday afternoon, the fuel companies advised the airlines and MBIE that they would be imposing rationing of fuel at Auckland Airport at 90%, as of midday the following day. They also advised MBIE that there were good levels of petrol and diesel on hand at the refinery and they were trucking more from Tauranga to conserve stocks at Wiri.

10.13 It was 6pm on Friday night when Refining NZ exposed the pipe and realised that the problem was substantial. Refining NZ’s board was informed at 6.30pm that the repair would take longer and serious rationing would be needed. The board includes representatives from the fuel companies. At 6.50pm, the supply managers in those companies were told it was not a pinhole leak and that the repair time was not known, but would probably be at least a week.

10.14 Across the morning on Saturday 16 September, Refining NZ confirmed to the supply managers, and later to MBIE, that the damage was larger than a pinhole leak and that the estimated time to repair would be 10–14 days from that day. MBIE passed the news on to DPMC, other senior officials, and Ministers. Supply managers passed the news on to their customers.

Table 6: Communication activities during the 2017 outage

|

Date |

Pipeline repair steps |

Communication and coordination steps |

|---|---|---|

|

Thurs 14 |

11:56am: Fuel stops flowing in RAP 2.40pm: Refining NZ finds leak site, secures it, contains leak. |

By ~4pm: Refining NZ informs WOSL, fuel companies, Minister, MBIE about leak, indicates estimated repair time of 48 hours, and that at that stage they do not anticipate an impact on Auckland product supply. Fuel companies inform airlines about leak and estimated 48-hour repair time. Refining NZ posts on Facebook about leak and expected repair time. |

|

Fri 15 |

6pm: Refining NZ exposes pipe. |

11am: Refining NZ tells fuel companies that revised estimate is 2–7 days from the following day. 2.30pm: MBIE told about estimated repair time; MBIE advises MCDEM. ~4pm: Fuel companies advise there will be jet fuel rationing at 90% at Auckland Airport, effective from midday the following day. ~6.30pm: Refining NZ board and fuel companies told damage is substantial, repair will take longer, and significant jet fuel rationing will be needed. |

|

Sat 16 |

Refining NZ assesses damage, repair options. |

10am–12pm: ~Refining NZ informs fuel companies, MBIE that repair estimate is 10–14 days. MBIE tells DPMC, Ministers about estimated repair time. Fuel companies consult airline representatives about proposed rationing. 3.12pm: NOC report indicates that there will be fuel rationing at Auckland Airport at 30%, effective immediately. Fuel companies tell airlines about fuel rationing decision. DPMC activates National Security System and calls Watch Group meeting. |

|

Sun 17 |

Refining NZ begins to remove and replace damaged section of pipe. |

Refining NZ notifies New Zealand Stock Exchange (NZX) of leak and estimated repair time. Meeting of MBIE, MOT, and MCDEM. Teleconference of central and local government agencies, Refining NZ, fuel companies, Auckland Airport, and airlines. 11:30am: ODESC decides to use NCMC to coordinate the response. Fuel companies tell MBIE repair will take 12–16 days. MBIE asks fuel companies for information on fuel stocks. MBIE issues situation report. Refining NZ tells Minister’s office about expected timeline. 9.18pm: MBIE tells Refining NZ they are central point of contact for the Government. Refining NZ tells MBIE of expected timeline. |

|

Mon 18 |

|

6am: Officials begin to use NCMC, led by MBIE (14 agencies from central and local government involved). Daily “chief executives teleconference” established between the Government and industry. Watch Group meeting; ODESC meeting. Z Energy representative joins NCMC to help with communication. |

|

Tues 19 |

|

Daily “chief executives teleconference”. Refining NZ representative joins NCMC. |

|

Wed 20 |

|

Daily “chief executives teleconference”. Government begins daily press conference. Watch Group meeting; ODESC meeting. ODESC creates new Fuel Security Working Group (FSWG) to operate out of Auckland Airport. CE of MOT to Auckland to chair it. Key aim is to provide a single view of fuel stocks and flows. |

|

Thurs 21 |

New section of pipe welded into place. |

Daily:

Watch Group meeting on 22 Sept. |

|

Fri 22 |

Lloyd’s approves repairs. |

|

|

Sat 23 |

Repairs certified. |

|

|

Sun 24 |

Pipeline resumes operation. |

|

|

Mon 25 |

First jet fuel certified, available at airport. |

|

|

Tues 26 |

|

|

|

Wed 27 |

|

Daily press conference. Debrief session at NCMC, before it closes down. |

10.15 On Saturday afternoon, after consulting with airline representatives, the Operating Committee of the JUHI decided that fuel would be rationed at Auckland Airport at 30%, effective immediately. A draft of the proposed NOC communication notifying the decision was sent to Air New Zealand for review, before being sent out at 3.12pm. The fuel companies also told their individual airline customers and Auckland Airport about that decision that afternoon. Air New Zealand, for example, received a formal email about the allocation from Mobil at 4.24pm, and from BP at 5.25pm. The Mobil email included the total amount of fuel available to Air New Zealand over the first five days under the rationing regime. The BP email included further explanation of how the rationing would work.

10.16 Refining NZ issued a statement to NZX about the leak on Sunday 17 September. It was published when the market opened on Monday 18 September.

Coordination efforts over the first few days of the outage

10.17 Over those first few days, the companies involved all took steps to coordinate information and activity.

- Refining NZ and the three fuel companies all initiated their internal emergency response procedures immediately. These protocols are designed to ensure internal communication to, and oversight by, appropriate personnel and to confirm roles and responsibilities internally to ensure effective decision making.

- The three fuel companies set up several joint working groups to coordinate different work streams, including a group of supply managers to coordinate all activities and one group specifically tasked with ensuring integrity of internal and external communications.

- Mobil, as the current chair of the supply managers’ forum, became the lead for the response (including the working teams and the communications team) on behalf of the three fuel companies.[4]

10.18 Based on the advice from Refining NZ and the fuel companies, MBIE’s initial assessment on Thursday 14 September was that a 24- to 48-hour outage was unlikely to cause supply issues. They maintained a watching brief and awaited information updates from Refining NZ and the fuel companies. When the estimated repair time changed from 48 hours to up to one week, MBIE alerted the Minister’s office and MCDEM, and informed them that rationing at 90% was to be imposed. MBIE also prepared advice on indicative impacts if the outage were to last longer than a week.

10.19 Around the middle of the day on Saturday 16 September, Refining NZ and then Mobil advised MBIE that the repair would take 10–14 days. At that point, MBIE informed DPMC and continued to communicate with fuel companies and Refining NZ to obtain regular updates.

10.20 In the evening, MBIE briefed senior Ministers by teleconference. It was agreed that the Minister of Energy and Resources would assume the role of lead Minister for the response. That evening, DPMC convened a Watch Group, made up of representatives from MBIE, MOT, DPMC, MCDEM, and New Zealand Police, to monitor the situation. DPMC also scheduled a meeting of ODESC for Sunday morning.

10.21 On Sunday 17 September, a teleconference was held between MBIE and the fuel companies, as well as with other departments, regional emergency management bodies (Auckland CDEM, Waikato Emergency Management), Refining NZ, Auckland Airport, and airline representatives. Later that morning, ODESC met and, among other things, decided to appoint MBIE as the lead agency, supported by MCDEM, MOT, and NZDF. It was decided that MBIE would use the NCMC in the bunker below the Beehive to help with communication and coordination.

10.22 The Government’s response efforts continued on Monday 18 September, now based in the NCMC and led by MBIE. Officials from the relevant government agencies, including MCDEM, MOT, and NZDF, were involved and were communicating with Auckland Council, NRC, and Auckland CDEM, as well as fuel companies and Refining NZ. That evening, they were joined by a representative of the fuel companies (provided by Z Energy), and the following morning, by a representative from Refining NZ. We were told that the initial work of the team based in the NCMC focused on two main priorities: information gathering and preparing government agencies to support industry where necessary and appropriate.

10.23 A “chief executives’ daily teleconference” was established between government and industry, which included the chief executives of MBIE, DPMC, and MOT; officials from the NCMC, Auckland Council, and other government agencies; and representatives of BP, Z Energy, Mobil, Refining NZ, Air New Zealand, Qantas, Board of Airline Representatives New Zealand (BARNZ), and Auckland Airport.

10.24 Between Sunday and Wednesday, MBIE began to gather information from fuel companies about jet fuel and ground fuel stock levels, to build a picture of the situation and prepare for any further contingency.

The establishment of the Fuel Security Working Group

10.25 After two more days, following one of the teleconference meetings, the ODESC chief executives decided to send an ODESC chief executive to Auckland to convene face-to-face meetings on the ground there, to enable more effective communication. The chief executive of MOT was nominated and went to Auckland that afternoon. Everyone we talked to confirmed that this step markedly improved the communications and reliability of information being shared.

10.26 From the afternoon of Wednesday 20 September, the FSWG met, in person, at Auckland Airport. It included representatives from the airlines, BARNZ, Z Energy, Mobil, BP, Auckland Council, MBIE, Auckland Transport, Refining NZ, Auckland Airport, MCDEM, MOT, KiwiRail, and NZDF. The minutes from the first meeting state that the purpose of the meeting was “to create one version of the truth by bringing together and clarifying information”. Its main advantage was that it put everyone in one room, rather than expecting information to cascade through the normal succession of commercial relationships.

10.27 The FSWG met in person or by teleconference daily between 20 and 27 September. It is clear from the submissions of many parties that the formation of the Working Group provided a significant shift in the coordination of information and response across the sector. One party said:

Given the diverse range of complex, commercially focussed stakeholders, this forum became a critical cog in forming a consistent picture and obtaining key information.

Challenges in communication and coordination

10.28 The evidence received by the Inquiry showed that over the course of the outage, both government and industry worked hard in a difficult situation to keep each other informed of developments, to build a clear picture of the extent of the problem, and to coordinate their efforts.

10.29 However, several parties told us communication was a challenge over the first few days of the outage.

10.30 Some parties told us that they were initially uncertain about the scale of the outage and the appropriate response. A degree of uncertainty across the first 48 hours was unavoidable, as the scale of the damage to the pipe became apparent. However, two specific points were raised:

- Some parties suggested that Refining NZ was too low key in its early message and gave too much emphasis to the possibility of a pinhole leak that could be fixed within two days. They thought Refining NZ should have been clearer about what they did and did not know during that first 48 hours.

- Some parties described an absence of a shared understanding of the seriousness of the incident and the appropriate level of response.

10.31 As the outage continued, there were other challenges in exchanging, collating, and processing information about stocks to build a single picture of available fuel across the supply chain and across the country, and to keep that picture updated. We were told that the challenges included:

- frustration from industry in receiving multiple requests from different parts of government, including for data that they did not have readily available or that had commercial sensitivities or competition law issues that needed to be worked through;

- difficulty for the government in processing and aggregating diverse data, and slower than expected responses from industry in the early days; and

- airlines having difficulty understanding the immediate practical situation for their individual fuel allocations.

10.32 We note that some parties have already reviewed what happened and identified lessons from this event. In particular, MBIE carried out a thorough review of their response in November 2017, soon after the event. That review identified areas where they had experienced difficulty and steps to address those matters. We draw on this review in the description and analysis that follows.

The early message from Refining NZ

10.33 The documents that we have seen, and reports to us from various parties, have confirmed that the early message from Refining NZ on Thursday afternoon was that the pipeline was likely to be fixed within 24–48 hours. By 11am on Friday, the time estimate changed to 48 hours to a week to achieve a repair. However, Refining NZ had no information on the scale of the damage for the first 30 hours. Their time estimate was based on an assumption that it was likely to be a pinhole leak that could be fixed easily with a clamp.

10.34 Refining NZ told us that it considered a pinhole leak caused by localised corrosion was the most likely cause, based on industry knowledge and the apparent absence of any evidence at the site of outside interference. It had a repair plan and equipment ready for a leak of this kind.

10.35 Refining NZ kept the fuel companies and government up to date with developments as they occurred. As soon as they understood the full extent of the damage, on Friday night, Refining NZ immediately informed its board and the fuel companies. Refining NZ informed others, including MBIE, the following morning.

10.36 However, several parties criticised Refining NZ’s approach as having given too much reassurance during the first 48 hours. Our review has shown that the early message from Refining NZ in the first 24 hours meant that government agencies did not activate any crisis response systems over this initial period. This response contrasts with that of the fuel companies and Air New Zealand. For example, BP told us that their approach was always to assume the worst at the outset, then “walk the response back” if the issue proved to be smaller. Air New Zealand also decided on Friday afternoon to begin bringing in fuel on flights from Australia and other New Zealand airports, even though it did not learn the true extent of the outage until the next day.

10.37 Refining NZ told us that it tried to give a balanced view in all its external communication, and to strike the right line between creating unnecessary alarm and being overly reassuring. As a listed company, it was conscious of meeting its obligations under the New Zealand Listing Rules. All parties were conscious of the need to avoid creating an environment where people started to panic-buy fuel.

10.38 In our view, the message conveyed by Refining NZ was overly optimistic in the first 24 hours. Parties, particularly those that were one step removed, such as airlines, took it at its word that the problem should be resolved within one or two days. They were later surprised when this proved not to be the case. We consider that this change exacerbated the confusion and stress of the situation.

A shared understanding of the outage and the appropriate response

10.39 Some parties noted that there was no shared understanding of what the response should be in the initial stages. For example, one party explained that while it knew how to respond to disruption events, it “does not know how that response necessarily corresponds with that of others”, and that “more coordination at the front-end about how parties view the seriousness of a fuel supply disruption event would be helpful”.

10.40 Other parties outside the fuel industry, as well as local government, also noted that there were different understandings about who should be doing what during the outage. For example, Auckland Council expressed concern that they were not advised directly by the fuel sector about fuel stocks, despite their responsibility for lifeline utilities in the region. [5]

10.41 While there was regular communication between the different parties, it appears that until several days into the outage, there was no explicit conversation between the parties to ensure they all had a shared understanding of how the response effort should be managed.

10.42 To be clear, the situation never reached the threshold for the Government to declare either a fuel shortage under the Petroleum Demand Restraint Act or a local or national emergency under the CDEM Act, and so these frameworks were not invoked. MBIE told us this meant that the core of the government role was to monitor the situation in case problems escalated, and to provide logistical support to a response that was otherwise led by industry.

10.43 MBIE also told us that they used the 2012 Fuel Plan to guide their response, but did not invoke it explicitly, as parts of the framework were unnecessary. For example, it decided to deal with just those fuel companies that were affected by, and responsible for, the RAP outage, through the companies’ nominated representative (Mobil), rather than engaging with all fuel companies in the particular structure required by the plan.

10.44 These assessments were reasonable responses to this specific situation. However, in our view, it would have been preferable for have had more direct discussion, at an early stage and among all parties who could have a role in the response, about the status of the issue in terms of CDEM and the 2012 Fuel Plan. This would have allowed all parties to understand exactly where the issue stood in a shared framework. It does not appear that this discussion ever took place. We think this added to the uncertainty, particularly for those who were not as intimately involved in the response.

10.45 The Inquiry’s view is that there is scope for MBIE to take more of a leadership role in ensuring this shared understanding across all relevant parties. This is an important step, even when it is assessed that the level of the outage is such that industry can effectively manage the response.

Sharing information about fuel stocks

10.46 Once the extent of the outage was understood, the fuel companies, in consultation with representatives from the airlines, decided to ration jet fuel at Auckland Airport to 30%. The final decision was communicated promptly to the airlines and Auckland Airport directly, as well as through NOC communications. The fuel companies told government there were sufficient stocks of jet fuel to cover up to 14 days of demand at that 30% allocation, and sufficient ground fuels to meet normal demand over the expected outage period.

10.47 MBIE told us it did not need information about stock levels that was more detailed to be able to carry out its role at that time. However, over the next few days it needed to obtain a bigger picture of the situation, to build its understanding of stock levels and flows around the country. It also needed to monitor how well airlines were tracking against the allocation, so that it could provide assurance to Ministers and make plans in case any further disruption took place.

10.48 From Sunday 17 September, MBIE made a series of requests for relevant information from fuel companies, including daily reports of stock levels of jet fuel at Wiri and JUHI, as well as stocks levels and replenishment schedules at other ports and airports around New Zealand. MBIE also asked the fuel companies to report daily on some information about retail stocks for ground fuels, as well as information about truck logistics.

10.49 MBIE told us that in requesting this information, they were guided by information-sharing protocols from the 2012 Fuel Plan; however, some types of information that they requested (in particular, retail-level information) went beyond this plan.

10.50 MBIE noted it was more challenging than expected to obtain certain information. They had some concerns that aggregated fuel stock information, covered by the 2012 Fuel Plan, was not initially provided as promptly as expected. For example, they told us they received information about jet fuel levels at Wiri and JUHI later than anticipated on Monday and Tuesday. MBIE told us that some companies were slow to provide the company-specific information and they had to take additional steps to obtain cooperation from some fuel companies.

10.51 For their part, some of the fuel companies told us they were frustrated by frequent requests for information from different parts of government, often for the same information or for information that they knew was irrelevant, or for information that the fuel companies did not necessarily hold themselves (such as retail-level information). To them, it seemed that officials did not sufficiently understand how the system worked to know what to ask for, or what the information they were getting meant. Mobil expressed this in their submission:

Throughout the pipeline outage, Mobil received highly granular data requests from multiple government agencies, often duplicated requests, meaning resources who were actively working to mitigate the impacts of the disruption were diverted from their core activity to hear and respond to requests or provide this data.

10.52 We heard that similar information was requested by MCDEM and NZDF, and in some cases, the Minister’s office. We also heard that that some information requested, particularly the information around ground fuels at retail sites, was not information that all fuel companies had immediate access to. In some cases, the information was sensitive and could not be shared between competitors.

10.53 From what we heard, it seems that a range of factors contributed to this initial difficulty in communication:

- MBIE response staff were not sufficiently familiar with the types of information that they received and did not have a full understanding of what information was appropriate to request or would be held by the fuel companies,[6] and what assurances might be required to allow the fuel companies to share that information.[7]

- MBIE response staff were also unfamiliar with emergency management procedures, including NCMC processes.[8] This resulted in some initial confusion between the roles of MBIE, MCDEM, and NZDF, among others. Key communication channels were not established, which in turn led to high amounts of information being requested and received.[9]

- On the part of the fuel companies, there was a corresponding lack of confidence in how information would be used, given the sensitivities around commercially sensitive information and the sharing of data between competitors. This required MBIE to engage at very senior levels to obtain the cooperation of the fuel companies in providing information.

- These factors led to a delay in information being provided and collated, and this in turn led others to turn to informal channels to obtain information.

10.54 By all accounts, these communication difficulties were largely resolved by Wednesday 20 September. However, in the Inquiry’s opinion, communication over the initial five or six days could have been improved by ensuring there were regularly revised and well-rehearsed plans, including protocols for the sharing of information around stock levels and for providing the necessary assurances to industry.

10.55 During the forum we held, we were repeatedly told by the industry that response plans must be kept “live” through regular discussion, revision, and practice. Although the 2012 Fuel Plan provided some guidance to MBIE on communication, it did not provide the necessary tools in this case. More regular revision and practice of the Plan might have ensured that the protocols covered all types of information that would be required by government and that any necessary competition law issues were worked through in advance.

Our findings on the communication and coordination efforts during the outage

10.56 We find that over the course of the outage, both government and industry worked hard in a difficult situation to keep each other informed of developments, to build a clear picture of the extent of the problem, and to coordinate their efforts.

10.57 Even so, it was clear that there were communication difficulties experienced by all parties over the first few days of the outage.

10.58 These difficulties were resolved over time and communication was greatly improved by Wednesday 20 September. As noted, many parties particularly commented that the development of the FSWG was helpful in improving communication across the sector.

10.59 In our view, Refining NZ was too optimistic in its early message over the first 24 hours that the outage would take 24–48 hours to resolve. This was based on an assumption on their part that the problem was a pinhole leak, at a time when they had no information on the extent of the damage. It would have been better if they had simply said they were investigating and should be able to say more once they had excavated and reached the pipeline. They could have given a time estimate for how long it would take to reach that point. We consider that this initial message added to the uncertainty in those early days.

10.60 However, as soon as they had seen the damage, Refining NZ provided clear and accurate information regularly to all those who needed to know.

10.61 This issue may not have made any difference to the timing of the decision by the fuel companies to move to ration jet fuel to 30% of normal allocations. That decision was made promptly once the full situation was understood and it was communicated quickly to the airlines.

10.62 In addition, while many parties independently took similar approaches to the outage, there was no shared understanding in the early days about the appropriate level of response. For example, there were different views on whether government involvement was needed at all, with some suggesting that the issue was within the scope of what could be managed by the fuel companies, without further help. We have concluded that there is scope for MBIE to take more of a leadership role in the early days of a disruption, to ensure there is a common understanding of the situation.

10.63 Even after the extent of the outage was understood, there were ongoing difficulties in gathering and collating data on fuel stocks to build a bigger picture of the issue and plan for any further contingency. This was partly due to a lack of familiarity among officials with the types of information held and commonly shared by industry, and the sensitivities around it, as well as a lack of confidence on the part of industry with regard to how the information would be used.

10.64 We find that the sharing of fuel stock information in the early days could have been improved if there had been clear, agreed, and tested protocols for obtaining information on stock levels that could have been picked up and used as soon as the extent of the outage was known. The existing protocols were insufficient for the types of data requested and the communication channels needed in this crisis. Regular revision and rehearsal of emergency plans could ensure that useful protocols are available and understood.

10.65 We acknowledge the efforts MBIE has already made through their own review work to identify areas for improvement, including the development of new information-sharing protocols. We encourage them to continue working on these improvements.

11. Managing the effects of the outage

11.1 By the morning of Saturday 16 September, Refining NZ was estimating that it would take another 10–14 days for the RAP to be operating again. This focused all parties on the stocks of fuel that were available in Auckland, how to make it last, and how to bring in product without the RAP. This chapter discusses the steps that were taken.

11.2 Table 7 shows the fuel stocks at Wiri on the day of the outage (14 September), the day the repair time frame was confirmed (16 September), and the last day before the RAP started operating again (24 September).[10] It clearly shows the way the fuel stocks were depleted across those 10 days.

Table 7: Fuel stocks at Wiri, 14, 16 and 24 September 2017

|

Fuel type |

14 September |

16 September |

24 September |

|---|---|---|---|

|

Petrol 95 |

1.5 days/0.689 million litres |

0.1 days/0.02 million litres |

0.0 days/0.01 million litres |

|

Petrol 91 |

9.2 days/20.9 million litres |

7.3 days/16.6 million litres |

3.2 days/6.5 million litres |

|

Diesel |

5.5 days/11.9 million litres |

4.8 days/10.4 million litres |

2.0 days/3.7 million litres |

|

Jet |

6.6 days/24.2 million litres |

4.8 days/17.8 million litres |

1.3 days/4.1 million litres |

11.3 Table 8 summarises the steps that were taken across the period of the outage.

Managing the consequences for jet fuel supplies

11.4 The outage removed the only existing supply line for jet fuel into Auckland Airport. While there was a good amount of jet fuel at Wiri, the JUHI tanks held less than normal because one tank was being serviced and so was out of use. To cope with the outage, the parties took steps to ration the use of jet fuel significantly and to find and establish alternative methods of supplying jet fuel to Auckland Airport.

Rationing fuel at Auckland Airport

11.5 As information on the scale of the potential outage became available, the three fuel companies followed established procedures to impose restricted allocations of jet fuel to the airlines. This approach is used internationally at airports whenever normal supply is disrupted. It involves setting a limit on the fuel that airlines can take from the airport, at a set percentage of their normal fuel use. For example, rationing to 80 or 90% of normal fuel use might occur if a weather event delays a ship. More severe rationing is rare.

11.6 A 30% allocation was imposed, effective from midnight on Saturday 16 September 2017. This meant airlines were allocated 30% of their usual usage at Auckland Airport. Each airline was told their total allocation amount over the following five days and it was up to the airlines to manage how they used that allocation. The restriction did not mean that only 30% of normal flights could proceed. Airlines have many ways to manage fuel restrictions at one airport. Each airline worked with its own fuel suppliers to put those into action. For example, they:

- used other domestic airports to refuel where possible;

- brought in more fuel on inbound flights where possible, to supplement outbound flights;

Table 8: Steps taken to manage the effects of the outage in 2017

|

Date |

Pipeline repair steps |

Steps to manage fuel supplies |

|---|---|---|

|

Thurs 14 |

11:56am: Fuel stopped flowing in RAP 2.40pm: Refining NZ finds leak site, secures it, contains the leak. |

|

|

Fri 15 |

6:00pm: Refining NZ exposed the damaged pipe. |

~4:00pm: Fuel companies advised there would be jet fuel rationing at 90% at Auckland Airport, effective from midday the following day. Air New Zealand began to fly in tanks of jet fuel. |

|

Sat 16 |

Refining NZ assessed damage, repair options. |

Refining NZ began work on a truck-loading facility at Marsden Point for jet fuel. MOT, MBIE investigated options for overweight fuel trucks on roads. 3:12pm: NOC report advised that there would be rationing of jet fuel at Auckland Airport at 30%, effective immediately. Airlines started on contingency arrangements (tankering in fuel, refuelling at other airports, reducing loads, cancelling flights). Fuel companies started to arrange to supply extra jet fuel to other airports, to enable refuelling out of Auckland. Fuel companies started to arrange for ground fuels to be supplied to Auckland from other ports (e.g., Wynyard Wharf, Mt Maunganui). |

|

Sun 17 |

Refining NZ began to remove damaged section of pipe. |

MBIE, NZDF discussed options for NZDF help with fuel companies. MBIE, Immigration changed transit visa rules so that planes could stop to refuel. |

|

Mon 18 |

|

|

|

Tues 19 |

|

Refining NZ’s truck-loading facility completed, subject to approvals. Options for a fuel barge, using NZDF jet fuel trucks, assessed and discarded. Confirmed that airport JUHI needed modifications to receive jet fuel from trucks. Option of using HMNZS Endeavour to transport fuel assessed. Confirmed that NZDF could provide 20 certified truck drivers. Contingency option of diesel from Huntly (Genesis Energy) agreed. |

|

Wed 20 |

|

NZTA and Auckland Council considered driver, load, and route permits for trucking jet fuel. Wynyard Wharf chemical tanks conversion to jet fuel storage assessed. Refining NZ trialled jet-fuel-loading gantry at Marsden Point. NZDF asked for staff to help with unloading at JUHI. |

|

Thurs 21 |

New section of pipe welded into place. |

HMNZS Endeavour travelled from Devonport to Marsden Point. |

|

Fri 22 |

Lloyd’s approved the repairs. |

Decision not to use HMNZS Endeavour. Jet fuel started being trucked from Marsden Point to JUHI (91,000 litres). Three trucks made available for transport of jet fuel. Jet fuel restrictions raised to 50%. |

|

Sat 23 |

|

HMNZS Endeavour returned to Devonport. Wynyard Wharf received fuel filter from NZDF. MT Matuku delivered 1.5 m litres of jet fuel to tank on Wynyard Wharf. Jet fuel trucked from Marsden Point (122,000 litres). |

|

Sun 24 |

Pipeline resumed operation. |

Jet fuel trucked from Marsden Point (150,000 litres). |

|

Mon 25 |

First jet fuel (from pipe) certified, available at airport. |

NZDF on site at Wynyard Wharf to assist. Jet fuel restrictions raised to 80%. Additional truck available for transport of jet fuel. |

|

Tues 26 |

|

First jet fuel trucked to JUHI from Wynyard Wharf. Two additional trucks available for transport of jet fuel. |

|

Wed 27 |

|

|

|

Thurs 28 |

First fresh jet fuel available at Auckland Airport. |

|

|

… |

|

|

|

Sat 30 |

|

Jet fuel allocations removed; supply back to 100%. |

- made “technical stops”, diverting outbound long-haul flights, to allow refuelling at Australian or Pacific island airports;

- reduced cargo or passenger numbers, to reduce the fuel used for individual flights;

- flew in some aircraft without passengers, specifically to transport in fuel; and

- where necessary, cancelled some flights.

11.7 These efforts by airlines kept flight cancellations to a minimum. They required substantial effort by the airlines and there was still disruption for passengers whose flights needed extra stops, with delays and missed connections.

11.8 Other parties took steps to help as well:

- Auckland Airport allowed more flights to use a fuel-efficient approach path and facilitated wing-to-wing transfer of fuel between planes.

- The fuel companies brought some additional fuel into other regional airports, to enable higher jet fuel use in those ports.

- Z Energy worked with Christchurch Airport to enable throughput of double their usual jet fuel volumes, to support the fuelling stops at that airport.

11.9 The restrictions were gradually lifted as certainty around the repair of the pipeline grew. Allocations were lifted to 50% on Friday 22 September after the pipe repair had been completed. They were raised again to 80% from Monday 25 September, after the first batch of fuel had arrived at Wiri through the RAP.

11.10 Allocations were finally lifted back to 100% on 30 September, 17 days after the initial pipeline shutdown.

Finding other ways to transport jet fuel to Auckland Airport

11.11 The fuel companies, together with Refining NZ, also looked for alternative ways to bring jet fuel to Auckland Airport, considering several different options. Across the course of the outage they managed to create two temporary methods for transferring jet fuel from the refinery to the airport:

- truck transfer of fuel from the Marsden Point refinery to the JUHI; and

- transfer by ship from Marsden Point into Wynyard Wharf in Auckland, followed by truck transfer from the wharf to the JUHI.

11.12 These supply routes had to be set up from scratch. It took a lot of work to get all the necessary legal arrangements and approvals in place, to put in place new or modified infrastructure and equipment, and to test all the equipment and procedures, before they could become operational.

11.13 For the trucking option, the tanks holding jet fuel at the refinery did not have facilities to allow trucks to load directly from the tank. Refining NZ immediately began work on converting a jet tank to allow trucks to load, with the help of experts from BP. The facility was completed by 19 September, but it took a further three days to be tested and approved by the fuel companies who would be using it, before trucking began. The fuel companies supplied the trucks and NZDF provided some drivers. The first two trucks transferred fuel from Marsden Point to JUHI on 22 September, eight days after the RAP shut down and only two days before it became operational again.

11.14 Over the same period, BP worked to establish a system to ship jet fuel directly to Auckland. Wynyard Wharf had tanks that had been used for petroleum before the RAP was built. More recently, the wharf has been managed by Stolthaven, which uses the tanks for storing chemicals. BP arranged with Stolthaven to clean and modify three tanks so they could receive jet fuel from a tanker. COLL arranged for the ship MT Matuku to be loaded with jet A1 at Marsden Point and transport it to Auckland. The ship began to transfer the fuel to the tank in Auckland on 23 September. That was followed by a necessary waiting period and the resolution of some final technical issues. On 26 September, trucks supplied by the fuel companies began transferring fuel from Wynyard Wharf to the JUHI. This was two days after the RAP was operating again, but it helped to replenish jet fuel stocks.

11.15 Both temporary supply routes needed cooperation from other parties to manage the additional truck traffic:

- NZTA gave approval for trucks carrying jet fuel to use the Johnstone Hill Tunnel at the northern end of the Northern Motorway, which made the road journey from Marsden Point faster.

- Panuku Development Auckland needed to put in place traffic management plans for truck movements on Wynyard Wharf.

- Auckland Transport worked with the fuel companies to confirm trucking routes and allow the use of bus and transit lanes.

- Auckland Airport put in place traffic management plans for trucks bringing fuel into the JUHI, which is close to roads around the domestic terminal.

11.16 The use of both these supply routes was limited by the truck-loading or discharge equipment at each end. For example, the Marsden Point tank could allow only one truck to load at a time and the Wynyard Wharf facility could support a maximum of six truckloads per day. At the JUHI, the WAP had to be stopped as appropriate to allow for truck transfer into the JUHI.

11.17 Another significant limiting factor was the lack of suitable trucks and drivers. Nationwide, only a small number of trucks are equipped and certified to carry jet fuel, and some of these were already being used to support the extra jet fuel being supplied to support refuelling at regional airports. Diesel trucks can be adapted to carry jet fuel, but this conversion can take several days and at this point, all the ground fuel trucks were being used to maintain the supply of ground fuel. In addition, drivers need to have special training before they can operate a jet fuel truck.

11.18 The FSWG calculated that it would be desirable to have seven trucks transferring fuel from the refinery to the JUHI – however, only three trucks operated on this route up to 26 September. By 27 September, a total of six trucks were transferring jet fuel to the JUHI from both the refinery and Wynyard Wharf. NZDF provided 18 drivers to drive the trucks, as well as trained staff to help transfer the fuel at both Wynyard Wharf and the JUHI.

11.19 In total, around 1.5 million litres of jet fuel was supplied to Auckland Airport via ship and truck from Wynyard Wharf, and a further approximately 700,000 litres was supplied by truck directly from the refinery. Some of this fuel only arrived at the airport after the outage was over, but it did help to replenish jet fuel stocks. Although 2.2 million litres may seem a large amount, it equates to approximately half a day of average daily demand at the JUHI.

11.20 Other supply options, and other options to increase the rates of supply, were considered but discarded. For example, the possibility of establishing floating storage in Auckland Harbour was investigated by the fuel companies, but ultimately not pursued. NZDF offered to provide additional road tankers from the vehicles they used on airfields, but these were not used as they were not fitted with the same protectors as typical road tankers and would have required additional safety measures. Options for working with NZTA to increase maximum permissible truck weights and maximum driving hours for drivers were also considered but not pursued.

Managing the consequences for ground fuel supplies

11.21 The management of ground fuel supplies was more straightforward. The fuel companies were able to arrange for COLL to ship ground fuels from the refinery to Mount Maunganui. The fuel companies also organised additional imports of fuel, depending on their customer requirements. All companies managed their respective truck fleets to deliver ground fuels from both Mount Maunganui and the truck-loading facility at Marsden Point into the Auckland area.

11.22 As ground fuels are usually delivered by truck, a reasonable number of trucks and drivers were available to support this increased workload.

11.23 Diesel supply was supported by using some existing storage at Wynyard Wharf, which received additional diesel directly during the outage. This facility was used to support the Wiri capacity for several months after the outage. HMNZS Endeavour was deployed to Marsden Point in case it was needed to transport diesel into Auckland. The Inquiry was told it returned to Devonport when an oil company decided against using a single hulled ship.

11.24 NZTA facilitated the additional fuel truck traffic for ground fuels by fast-tracking requests to relax vehicle weight restrictions by granting High Productivity Motor Vehicle permits, and requests to change the requirements regarding driver hours and hazardous substances. Auckland Council also worked with the fuel companies to waive delivery period restrictions.

11.25 Across the period of the outage, a small number of individual petrol stations ran out of high-octane fuels, but there was no region-wide shortage. However, by 26 September, at least one fuel company reported a risk of a large number of petrol stations running dry if stocks were not replenished soon.

11.26 Towards the end of the outage period, it was clear that ground fuel stocks were running low. For that reason, the Slate Committee that controls the RAP decided that once it started operating again, the first batches through the RAP would be jet fuels, then ground fuels, then jet again, rather than the RAP being used back-to-back for the resupply of jet fuel.

What was the overall impact?

11.27 While the public impact of the outage was kept to a minimum, it should not be understated. Because of the jet fuel rationing, around 270 flights were disrupted, including cancellations, rescheduling, and flights requiring fuel stops. Although there were no overall ground fuel supply restrictions, stocks were starting to run low by the end of the outage, which suggests that the alternative supply routes were not keeping pace with demand. Therefore, the second batch of fuel sent down the RAP, when it resumed, was ground fuel.

11.28 The steps taken by the sector minimised the impact of the RAP outage, but they came at a significant financial cost:

- It cost the airlines a lot to minimise passenger and cargo loads, add additional stops, bring in fuel in empty planes, and cancel and reschedule flights.

- The fuel companies bore the costs of developing the alternative supply methods and bringing fuel to Auckland by truck and ship.

- Refining NZ paid to establish a new truck-loading facility for jet fuel at the refinery and had to slow down production.

11.29 In addition, there was the cost of repairing the RAP, including bringing in equipment and experts from overseas, and remediating the site of the leak. Refining NZ was responsible for most of this expense, but the fuel companies and others provided substantial technical support.

11.30 Eight parties were able to provide the Inquiry with estimates of their direct costs. From these parties alone, the total was around $25 million.[11] However, most of them stressed that the real costs were much higher. They made no effort to quantify the time that staff, including senior management, spent on the issue, or indirect costs like lost business or the displacement of their normal activities. Nor did this figure include the cost of the time that government agencies put into the outage.

11.31 In addition to these direct costs, there would have been a cost to the economy from reduced or constrained activity. Chapter 1 referred to some modelling work that had been done for MBIE on the costs of different outage scenarios (see paragraph 1.16), including a scenario involving a short-term outage of the RAP or the Wiri facility. The modelling suggested that New Zealand would suffer a loss of $23 million of GDP.[12]

11.32 The outage also had the following impacts:

- Government agencies and other organisations put in place travel restrictions for their staff.

- NZDF ceased all but essential flying operations, altered its international flight routes to refuel overseas, and cancelled the last week of a jet-flying training exercise with another country.

- Many airline passengers had their travel plans disrupted.

- All parties assume that there was some reputational damage to New Zealand and Auckland as a destination, as well as to the fuel sector and airlines.

- There have been environmental consequences for the land affected, although we acknowledge that Refining NZ made every effort to minimise these.

- The owners of the affected properties at the site of the rupture have all suffered significant disruption and some economic loss, because their land now carries a contamination warning on the title.

11.33 It is also clear that the impacts could have been significantly greater. For example, if the fuel in the pipeline at the time of the disruption had been petrol, there would have been a higher risk of explosion from vapour clouds, as well as a fire risk and greater risk to human life. If the rupture had occurred in a different location – for example, a built-up environment, a remote location that was difficult to access, or a location close to a water source) the costs of repair and the time taken could have been significantly higher.

11.34 In addition, if the repair had taken longer for any reason, the impact of the outage would probably have been worse

- If the outage had continued into the peak travel period during the school holidays, which began on 30 September, the disruptions would have affected a significantly larger number of people.

- The refinery may have had to halt production because of limited storage on site.

- Ground fuel supply would probably have started to struggle to meet demand, affecting transportation across Auckland, including emergency services and public transport. It might have been necessary to start prioritising fuel supplies to lifeline utilities and emergencies, and possibly rationing retail supplies.

Our findings on the way the effects of the outage were managed

11.35 There was extensive cooperation across the sector to manage the fuel supplies during the outage, to minimise the disruption for airline passengers and other consumers. Central and local government did what they could to support the efforts of the private sector companies – for example, by helping the companies work through regulatory requirements quickly.

11.36 The result was that effective alternative supply routes were adapted and adequately scaled up in the case of ground fuel. In the case of jet fuel, temporary routes were developed from scratch within the span of one to two weeks.

11.37 We acknowledge that people worked hard to find practical solutions quickly. Each company in the fuel industry had good response plans and systems governing their individual actions.

11.38 Nevertheless, in relation to jet fuel at least, quite severe rationing was required and airlines had to take strong measures to minimise disruption to passengers as far as possible, at significant cost to themselves. Auckland Airport noted that many of the measures taken by the airlines may not have been possible – at least to the same extent – had the outage occurred during the much busier school holiday period two weeks later, and the effects would then have been more severe.

11.39 We find that the fuel sector had not taken practical steps to establish the contingency arrangements, equipment, and approvals it would need to bring jet fuel to Auckland Airport in this type of situation. It had to start from scratch to create temporary alternative supply routes. This caused delay. Fuel only began to be delivered directly from the refinery eight days after the outage began, and the route via Wynyard Wharf did not become operational until 12 days after the outage, by which time the RAP was operating again. In addition, the amount of fuel that could be provided through these routes was small when compared with the normal daily usage at the airport. In essence, it was too little, too late.

11.40 It is also important to note that the Wynyard Wharf route is no longer available. This reduces the options for bringing jet fuel to Auckland even further. At present, trucking from Marsden Point is the only back-up option available.